ҮЙЛЧИЛГЭЭ

Дело клиента

2018.11.5 The bulk of bauxite production is used as feed for the manufacture of alumina via a wet chemical caustic leach process known

узнать больше

2020.12.21 This paper examines the bauxite particle size requirements for the Bayer Process. A closed circuit Semi-Autogenous Grinding (SAG) mill with a hydrocyclone is

узнать больше

2022.11.3 The raw material for the Bayer process is most commonly mined bauxite, a rock containing aluminium, which – as we already know – also contains many other

узнать больше

2024.1.25 Its synthesis is based on the refinement of a mixed mineral ore, called bauxite, into alumina by means of the Bayer process (Fig. 1a), leaving the colloquially

узнать больше

2022.11.4 The raw material for the Bayer process is most commonly mined bauxite, a rock containing aluminium, which – as we already know – also contains many other

узнать больше

2022.1.23 Bayer Process Impurities and Their Management Steven J. Healy Chapter First Online: 23 January 2022 650 Accesses Part of the Springer Series in Materials

узнать больше

2024.1.9 This involves a number of key steps, including: Bauxite grinding; Slurry storage; Digestion; Clarification; Precipitation; and Calcination. simplified process flow

узнать больше

2023.8.22 The reduction of iron minerals of boehmitic bauxite in both the Bayer solution and purely alkaline solutions was carried out. Experiments were performed using

узнать больше

2023.12.13 Dr. Dmitri Kopeliovich Bayer process is the process of refining alumina from bauxite (aluminum ore containing 30-50% of hydrated aluminum oxide) by selective extraction of pure aluminum oxide dissolved in sodium hydroxide. Prior to the Bayer process bauxite is crushed and ground in mills to fine particles (max. size 0.06”/1.5mm). A hot

узнать больше

2018.12.4 The Bayer process produces alumina from the bauxite ore, and the Hall-Héroult process leads to the dissolution of the alumina powder into cryolite batch to produce the metal aluminum. In the beginning, the geographical pattern of the metal aluminum was extended with the investigation and exploitation of the large bauxite reserves in Western ...

узнать больше

2022.1.23 Of all Bayer process impurities, few attract more attention than the simplest dicarboxylate. While some oxalate enters the Bayer process with bauxite as oxalic acid adsorbed on various minerals , the majority is created by the oxidation and pyrolysis of bauxite organics under Bayer digestion conditions. The rate of its formation in digestion is ...

узнать больше

2023.4.17 Aluminum production from bauxite is achieved with the Bayer process, which is a hydrometallurgical method. However, in the Bayer process, in time, it is possible to encounter problems such as the formation of excessive amounts of red mud in aluminum production, its environmental risks, its requirement of large storage sites, the excessive

узнать больше

2015.4.1 The Bayer process was invented 130 years ago and remains the global method of choice for converting bauxite to alumina for aluminum and industrial alumina production. In general, the three largest problems in the Bayer process are as follows: (a) The removal of silica (a problem with high silica bauxite). (b)

узнать больше

2023.5.30 For the same grade of bauxite ore, using the traditional Bayer process, the theoretical maximum alumina dissolution rate is 77.1% and the Na 2 O mass fraction in the slag is about 10.0% (A/S = 1 and N/S = 0.608 in the red mud), while the actual dissolution rate of the Bayer process bauxite ore in this alumina plant is about 70%, which shows ...

узнать больше

2014.5.8 The bauxite ore, Bayer process materials before precipitation, mud residue, and sand residue are therefore of radiological interest, whereas the alumina product is not.8 Positional and personal monitoring data from bauxite mines and alumina refineries in Western Australia have been used to assess the above-background annual doses for the ...

узнать больше

2023.4.23 Aluminum (Al) Ore. Aluminum ore, also known as bauxite, is a naturally occurring mineral rock that contains aluminum in the form of aluminum oxide (Al2O3) mixed with various impurities. Bauxite is the primary source of aluminum, which is one of the most abundant elements in the Earth’s crust, comprising about 8% by weight.

узнать больше

2019.2.4 BAYER PROCESS Bayer process is the process of refining alumina. from bauxite (aluminum ore containing 30-50% of hydrated aluminum oxide) by selective extraction of pure aluminum oxide dissolved in sodium hydroxide. Prior to the Bayer process bauxite is crushed and ground in mills to fine particles (max. size 0.06”/1.5mm).

узнать больше

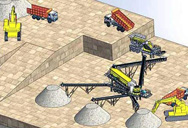

2022.1.23 3.1 Introduction to Crushing and Grinding of Bauxite. The most common initial process step to feed an alumina refinery with bauxite is the crushing or sizing of the raw bauxite material that is extracted from the mine. The feed material is crushed or sized so that it is conveyable, as well as correctly dimensioned, for the next step in the process.

узнать больше

Aluminum Production. Alton T. Tabereaux, Ray D. Peterson, in Treatise on Process Metallurgy: Industrial Processes, 2014 2.5.1.1 Impact of Different Bauxites on the Bayer Process. The Bayer process is basically used for the extraction of aluminum hydrate from the bauxite ores with the mass ratio of alumina to silica (A/S) above 9. The sinter process

узнать больше

2019.5.12 step is the separation of aluminium oxide from iron oxide and other impurities in bauxite. This is accomplished using a technique developed by Karl Joseph Bayer, an Austrian chemist, in 1888. In the Bayer process, bauxite is mixed with caustic soda, or sodium hydroxide, and heated under pressure.

узнать больше

2023.12.26 One of the issues encountered during the Bayer process is the presence of silica in bauxite samples, particularly in the form of Kln (Al 2 O 3.2SiO 2.2H 2 O) or reactive silica. This happens because it consumes all of the sodium hydroxide added during the digestion step and it also forms insoluble compounds that hinder the profitability of the ...

узнать больше

2015.12.12 The Al-oxyhydroxide minerals present in bauxite are amenable to mechanical activation due to easily breakable weak hydrogen bond which joins basic building blocks Al-(OH) 6 or AlOO(OH) 4 present in sheet configurations unique to each of the minerals. The first noteworthy effort to use mechanical activation in Bayer process

узнать больше

2020.2.7 BAUXITE AND ALUMINA1. Domestic Production and Use: In 2019, the quantity of bauxite consumed was estimated to be 5.1 million tons, 30% more than that reported in 2018, with an estimated value of about $162 million. About 73% of the bauxite was refined by the Bayer process for alumina or aluminum hydroxide, and the remainder

узнать больше

2020.1.23 In essence, with attrition milling, there may be a possibility of a universal Bayer process independent of bauxite mineralogy. Over the years, the capacity of attrition mills has significantly increased, from 200 to 10,000 L or more. Thus, there is a bright prospect for scale-up. The scope of the present study was limited to pure water.

узнать больше

2016.8.10 Rod mill tests under strongly alkaline conditions can be undertaken using the modified Rod Mill in order to simulate the circumstances of bauxite grinding during the Bayer process. Grinding work indices for bauxite in liquor reduce as a function of temperature (specific grinding energy decreases).

узнать больше

2021.2.4 BAUXITE AND ALUMINA1. Domestic Production and Use: In 2020, the reported quantity of bauxite consumed was estimated to be 4 million tons, slightly more than that reported in 2019, with an estimated value of about $110 million. About 79% of the bauxite was refined by the Bayer process for alumina or aluminum hydroxide, and the

узнать больше

Steps in Bayer process : (1) Ore Preparation : It is important to do ore preparation to reduce total precentage of silica in boxite. Using crushing and grinding, the silica content reduced from 10% to 1.5% as bauxite tends to get concentrated in the finer fractions (i.e., -100 mesh). Another importance of using finer bauxite is to increase ...

узнать больше

2018.11.5 The production process of Bayer alumina is shown in Figure 2. In the Bayer process, bauxite is leached with a hot solution of sodium hydroxide (NaOH) at temperature of 150–240°C and at 1–6 atm

узнать больше

2021.12.13 The Bayer process is almost always used to accomplish this, and consists of cooking large batches of crushed bauxite in a pressure vessel with a solution of caustic soda, or sodium hydroxide.

узнать больше

2023.7.24 The Bayer process is not easily explained in brief. This method of obtaining alumina from bauxite ore is complex and involves a lengthy succession of chemical reactions, with the process varying

узнать больше

2022.11.4 The Bayer process, i.e. the production of pure aluminium oxide hydrate (or more chemically formulated aluminium hydroxide) from bauxite, and the calcination process, i.e. the production of pure aluminium oxide from the aluminium oxide hydrate. However, these two processes are often combined in books and the media and referred to as “the

узнать больше

2015.8.14 Well-reacted geopolymers with good compressive strengths (44–58 MPa) were formed from highly alkaline residue from red mud (the residue remaining after extraction of alumina from bauxite by the Bayer Process) without the addition of strength-promoting components, such as fly ash or ground slag, by adjusting the composition to

узнать больше

2022.4.20 During the digestion process of the Bayer method, lithium and gallium in bauxite will enter into the sodium aluminate solution (Tang et al. 2020; Xu et al. 2018), which will return to the digestion process for recycling after the precipitation of aluminum hydroxide from the decomposition of crystal species.Due to a large amount of red mud discharge,

узнать больше

6 天之前 The Bayer refining process used by alumina refineries worldwide involves four steps: digestion; clarification; precipitation; and; calcination. Digestion. Bauxite is finely ground in mills, then mixed with a recycled caustic soda solution and steam in digester vessels operating at high temperature and pressure.

узнать больше

2022.8.20 Bauxite residue (BR) is a by-product of Bayer process, which is applied for alumina production. Due to its inherent alkalinity and sodicity, the use of BR is globally limited to 23% of the 150 million tons (Mt) produced annually.Maximizing alternative and large-scale uses of BR is a game changer to promote the sustainability of the aluminum

узнать больше

2022.11.11 The Bayer process is the most commonly used in alumina production (Liu et al. 2007), and more than 90% of alumina is produced by the Bayer process worldwide (Wang et al. 2018). Bayer red mud is an insoluble alkaline solid waste residue produced during the dissolution process of bauxite by the Bayer process (Zeng et al. 2022; Lyu et

узнать больше

2021.6.25 12.1.2.1 Bayer Process Description - In the Bayer process, crude bauxite ore is dried, ground in ball mills, and mixed with a preheated spent leaching solution of sodium hydroxide (NaOH). Lime (CaO) is added to control phosphorus content and to improve the solubility of alumina. The resulting slurry is combined with sodium hydroxide

узнать большеузнать больше